OUR SERVICES

OUR

SERVICES

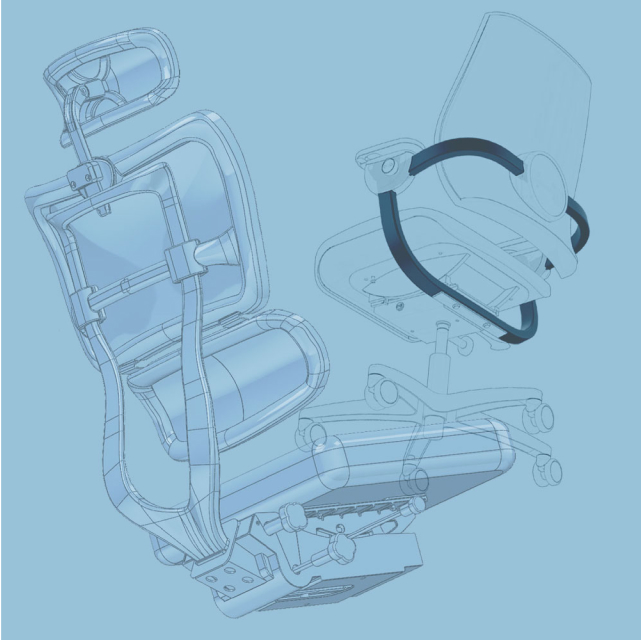

MTA Industries: Your partner in product design and development. We combine creativity, technical expertise, and market understanding to transform your ideas into exceptional products. Our multidisciplinary team crafts meticulously engineered prototypes, ensuring form and function are seamlessly integrated. With user-centered design practices and continuous iteration, we create captivating and commercially successful products. Collaborate with us and unlock the full potential of your ideas. Contact MTA Industries today for innovative solutions.

Click for more

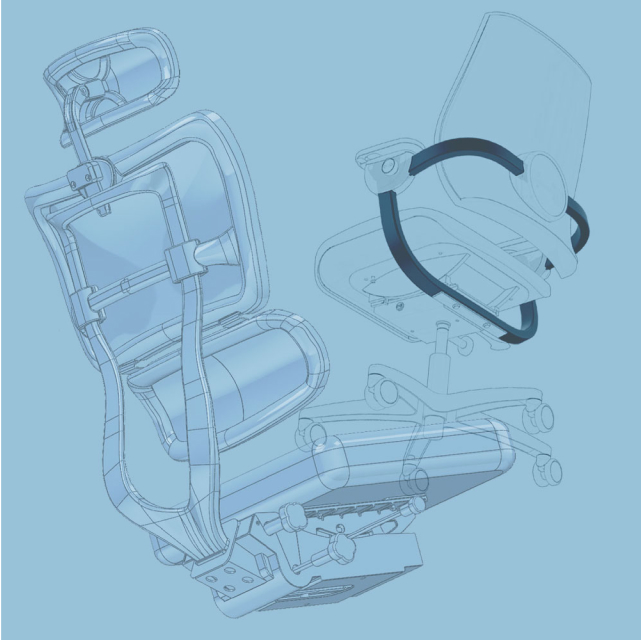

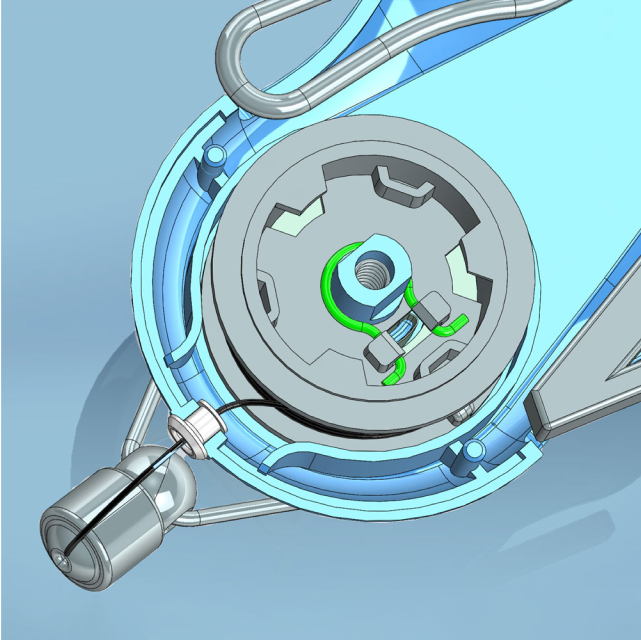

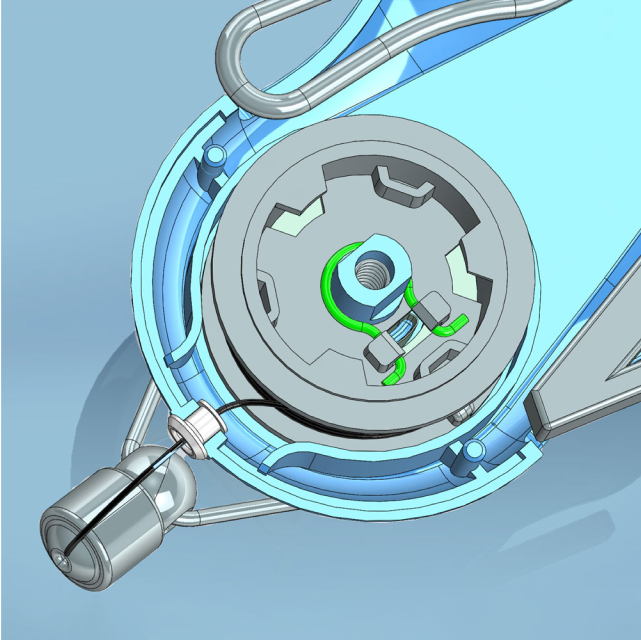

We offer expert Mechanical Design Engineering services tailored to meet each client’s specific requirements. Our experienced engineers utilize advanced software tools like CAD, FEA, and CFD to develop efficient and innovative designs. We prioritize open communication and collaboration with clients throughout the process to ensure the final design aligns with their specifications. Our rigorous testing and validation procedures ensure the designs are robust and reliable. Additionally, we provide support in project management, cost estimation, and manufacturing feasibility. Our goal is to deliver high-quality solutions that drive innovation and create value for our clients.

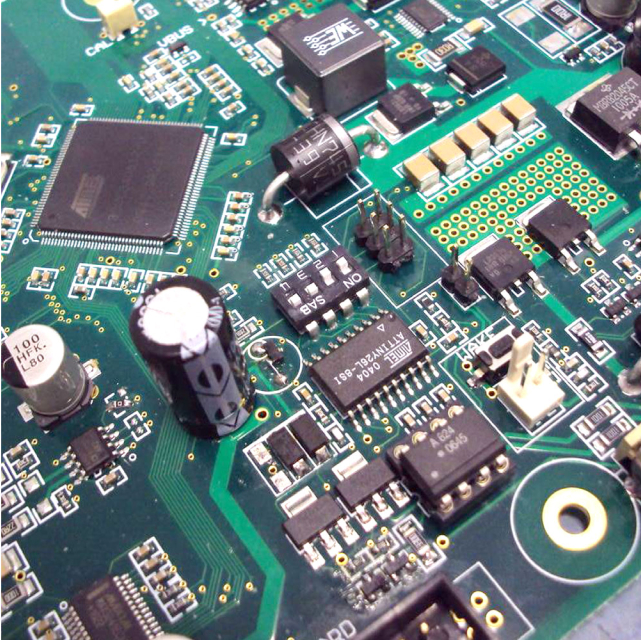

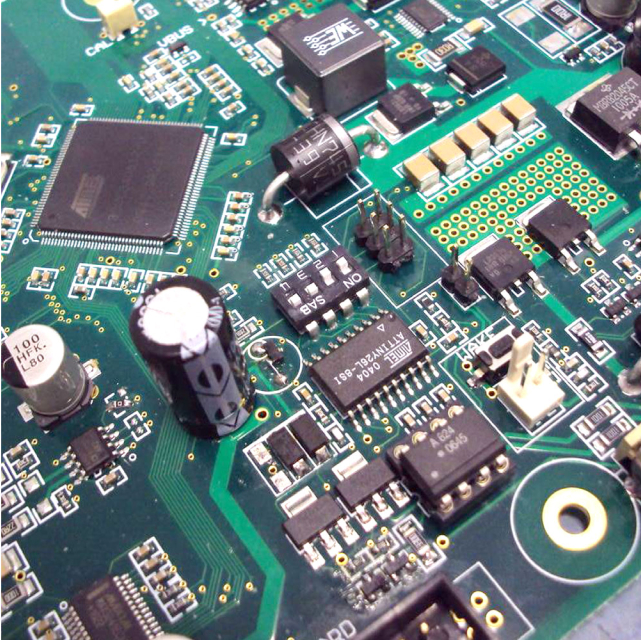

Our company offers comprehensive Electronic Design Engineering services. We gather client requirements and create detailed design specifications. Our skilled engineers use industry-standard tools to design circuits and PCB layouts, considering factors like signal integrity and thermal management. We select components based on cost, performance, and availability. We integrate subsystems and conduct rigorous testing and validation. We prioritize adherence to industry standards and stay updated with emerging technologies. Ultimately, we deliver high-quality designs that meet client requirements.

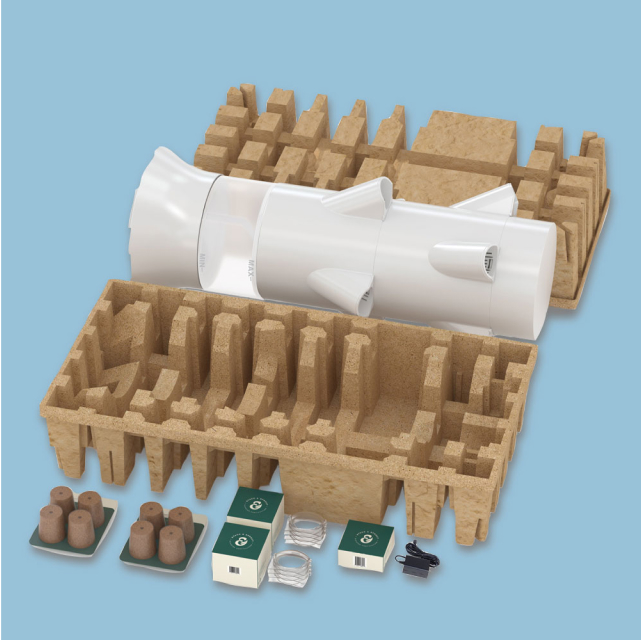

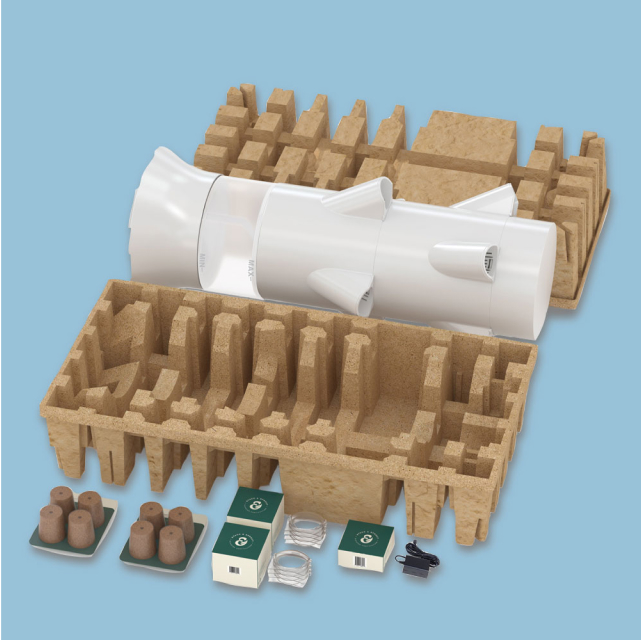

Our company provides clients with Packaging Design expertise through a systematic process that combines artistic creativity with technical proficiency. We begin by analyzing the client’s brand identity, target market, and product requirements. Our designers generate innovative packaging concepts, which are refined through collaboration with the client. Detailed structural designs are developed, considering material selection, manufacturing feasibility, and sustainability. Concurrently, our graphic artists create visually captivating artwork aligned with the brand’s identity. Prototypes are generated for evaluation, leading to the final design. We assist with the transition to mass production by providing technical specifications and supplier recommendations. Overall, our approach ensures visually appealing, functional, and cost-effective packaging designs.

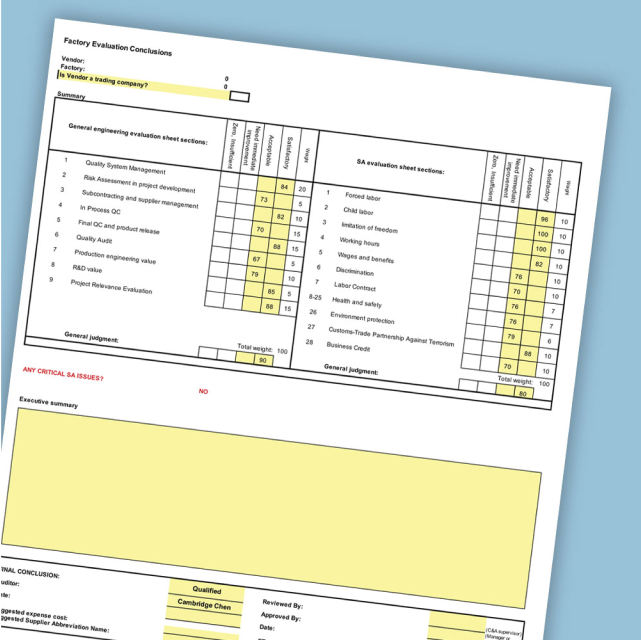

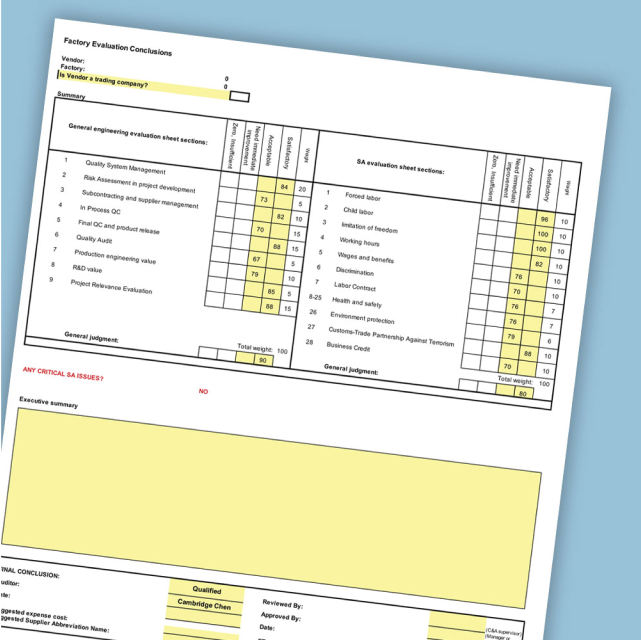

Our company offers comprehensive Factory Qualification expertise and services to ensure compliance with quality standards and regulations. We conduct detailed assessments of manufacturing processes, facilities, and documentation. Our experienced team utilizes statistical analysis and risk assessments to identify non-compliance and inefficiencies. We develop corrective action plans and provide documentation and training for sustainable compliance. Our ongoing support includes audits and performance evaluations to drive continuous improvement.

Our company offers specialized expertise in ESG, sustainability, and social compliance. We assess clients’ current practices and develop tailored strategies. We help them reduce their environmental impact, improve social compliance, and achieve sustainability goals. We align with recognized frameworks and regulations, provide audits and risk assessments, and offer training and capacity-building. Our focus is on empowering clients to embed ESG principles, enhance sustainability reporting, and drive positive change.

Issuance of PO’s by clients and electronic data entry of PO’s into TradeMaster™ – Scheduling and booking of MTA inspections into our online inspection APP.

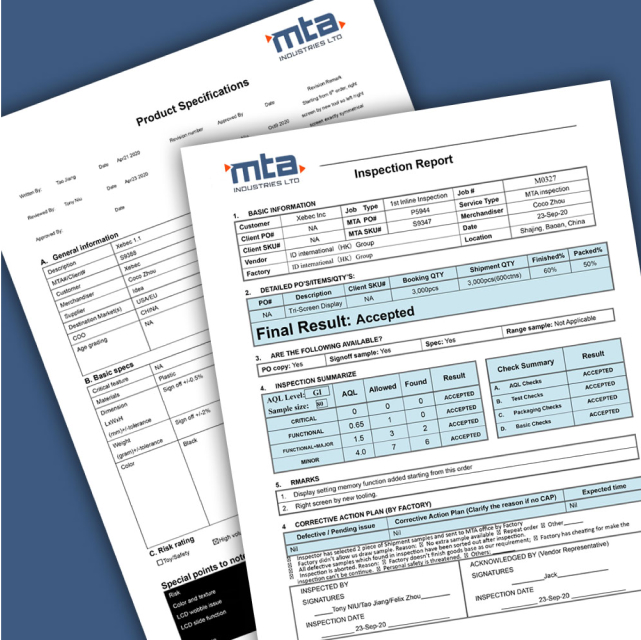

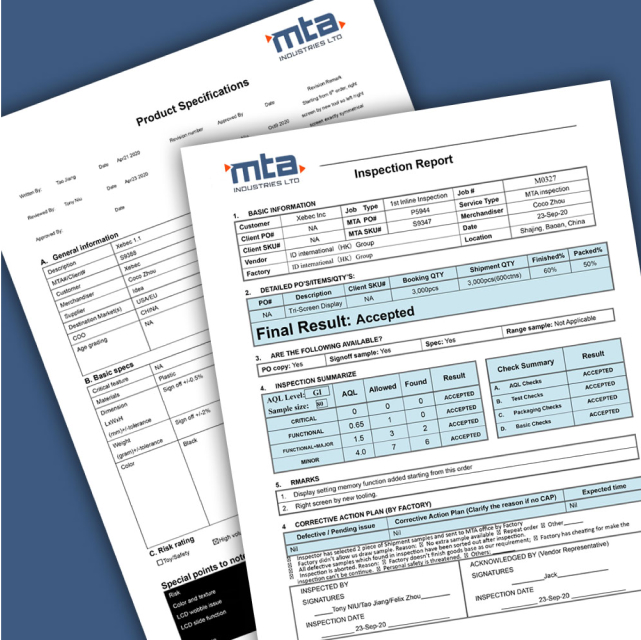

The basis for controlling all quality is: (For each Product/SKU)

- Golden Sign-Off Sample

- Product Specification Sheet

Quality assurance (QA) and quality control (QC) procedures are

implemented to maintain the highest product standard

For first time orders and pilot runs, final QC inspections can be conducted on 100% of the goods. US Military Standard Level is the most utilized AQL inspections criteria by MTA inspectors.

Our company provides logistics expertise and services to clients through the following technical approach:

- Logistics Analysis: We analyze clients’ supply chain needs and identify improvement areas.

- Supply Chain Design: We create customized supply chain designs using optimization techniques.

- Transportation Management: We optimize transportation with advanced systems for route planning, load optimization, and real-time tracking.

- Warehousing and Inventory Management: We use state-of-the-art systems to optimize inventory, storage, and order fulfillment.

- Order Fulfillment and Distribution: We streamline order processing, picking, packing, and shipping with integrated systems.

- Technology Integration: We leverage IoT, RFID, and barcode scanning for enhanced visibility and traceability.

- Performance Monitoring and Optimization: We measure KPIs, analyze data, and implement optimization strategies.

- Continuous Improvement: We continuously review and refine logistics processes to adapt to changing market demands.

- Through technical expertise and advanced technologies, we optimize supply chain efficiency and enhance customer experience.

- Design Product Development

MTA Industries: Your partner in product design and development. We combine creativity, technical expertise, and market understanding to transform your ideas into exceptional products. Our multidisciplinary team crafts meticulously engineered prototypes, ensuring form and function are seamlessly integrated. With user-centered design practices and continuous iteration, we create captivating and commercially successful products. Collaborate with us and unlock the full potential of your ideas. Contact MTA Industries today for innovative solutions.

- Mechanical Design Engineering

We offer expert Mechanical Design Engineering services tailored to meet each client’s specific requirements. Our experienced engineers utilize advanced software tools like CAD, FEA, and CFD to develop efficient and innovative designs. We prioritize open communication and collaboration with clients throughout the process to ensure the final design aligns with their specifications. Our rigorous testing and validation procedures ensure the designs are robust and reliable. Additionally, we provide support in project management, cost estimation, and manufacturing feasibility. Our goal is to deliver high-quality solutions that drive innovation and create value for our clients.

- Electronic Design Engineering

Our company offers comprehensive Electronic Design Engineering services. We gather client requirements and create detailed design specifications. Our skilled engineers use industry-standard tools to design circuits and PCB layouts, considering factors like signal integrity and thermal management. We select components based on cost, performance, and availability. We integrate subsystems and conduct rigorous testing and validation. We prioritize adherence to industry standards and stay updated with emerging technologies. Ultimately, we deliver high-quality designs that meet client requirements.

- Packaging Design

Our company provides clients with Packaging Design expertise through a systematic process that combines artistic creativity with technical proficiency. We begin by analyzing the client’s brand identity, target market, and product requirements. Our designers generate innovative packaging concepts, which are refined through collaboration with the client. Detailed structural designs are developed, considering material selection, manufacturing feasibility, and sustainability. Concurrently, our graphic artists create visually captivating artwork aligned with the brand’s identity. Prototypes are generated for evaluation, leading to the final design. We assist with the transition to mass production by providing technical specifications and supplier recommendations. Overall, our approach ensures visually appealing, functional, and cost-effective packaging designs.

- Factory Qualification

Our company offers comprehensive Factory Qualification expertise and services to ensure compliance with quality standards and regulations. We conduct detailed assessments of manufacturing processes, facilities, and documentation. Our experienced team utilizes statistical analysis and risk assessments to identify non-compliance and inefficiencies. We develop corrective action plans and provide documentation and training for sustainable compliance. Our ongoing support includes audits and performance evaluations to drive continuous improvement.

- ESG/Sustainability/Social Compliance

Our company offers specialized expertise in ESG, sustainability, and social compliance. We assess clients’ current practices and develop tailored strategies. We help them reduce their environmental impact, improve social compliance, and achieve sustainability goals. We align with recognized frameworks and regulations, provide audits and risk assessments, and offer training and capacity-building. Our focus is on empowering clients to embed ESG principles, enhance sustainability reporting, and drive positive change.

- Management through TradeMaster

Issuance of PO’s by clients and electronic data entry of PO’s into TradeMaster™ – Scheduling and booking of MTA inspections into our online inspection APP.

- Supply Chain Risk (QA & QC)

The basis for controlling all quality is: (For each Product/SKU)

- Golden Sign-Off Sample

- Product Specification Sheet

Quality assurance (QA) and quality control (QC) procedures are

implemented to maintain the highest product standard

For first time orders and pilot runs, final QC inspections can be conducted on 100% of the goods. US Military Standard Level is the most utilized AQL inspections criteria by MTA inspectors.

- Logistics

Our company provides logistics expertise and services to clients through the following technical approach:

- Logistics Analysis: We analyze clients’ supply chain needs and identify improvement areas.

- Supply Chain Design: We create customized supply chain designs using optimization techniques.

- Transportation Management: We optimize transportation with advanced systems for route planning, load optimization, and real-time tracking.

- Warehousing and Inventory Management: We use state-of-the-art systems to optimize inventory, storage, and order fulfillment.

- Order Fulfillment and Distribution: We streamline order processing, picking, packing, and shipping with integrated systems.

- Technology Integration: We leverage IoT, RFID, and barcode scanning for enhanced visibility and traceability.

- Performance Monitoring and Optimization: We measure KPIs, analyze data, and implement optimization strategies.

- Continuous Improvement: We continuously review and refine logistics processes to adapt to changing market demands.

- Through technical expertise and advanced technologies, we optimize supply chain efficiency and enhance customer experience.